A’ddition

My first ‘physical’ product project!

I have recently started an Interaction Design Foundation course on accessibility which inspired a new product idea for those with disabilities of any degree.

The Beginning

I was taking out the trash the other day, a task I and many others do often. I threw the full bags of various packaging in the larger bins outside and proceeded to take my green and blue bins out to the end of the driveway in preparation for collection the next day. Whilst I have had struggles taking these rather large and unruly bins out in the past, for some reason this time I really did notice how badly those things are designed. They are heavy when full and extremely difficult to manoeuvre with just two wheels that are stuck going either forward or backward. I frustratingly managed to wrangle each bin into the correct spot, leaving me to do some awkward shifting of each one to make sure they were facing the right way. After this I went back inside and continued working on my accessibility course with the Interaction Design Foundation. It was here when my brain made the connection: wheelie bins and accessibility. The relationship between these two things is virtually non-existent. So I thought well why not do a redesign of these common household wheelie bins with accessibility at the forefront of my design?

Research

I first went to work with some basic research. Does a more accessible version of these bins exist? Quick answer = no. Okay interesting, how about any designs for these bins in places like dribble? Again, no. To be honest I was quite surprised by this. I thought since almost everyone who owns/lives in a house uses these bins fairly frequently, this problem would have come up before and been addressed at least with some designs - alas this was not the case. There were indeed designs for fancy household bins and accessible household bins, but nothing for these outdoor wheelie bins.

User Personas

Sadly, I knew I didn’t have any access to user feedback from those with the disabilities I was designing for as this is just a small, hypothetical side project. So I did the next best thing, created personas to help me throughout the Project.

-

Persona #1 - Issac Bowen

Meet Issac, the 43-year-old artist, and musician!

-

Persona #2 - Alessia Willis

Meet Alessia, the 21-year-old translator, and gardener!

Please find the link to the Miro Board in which I created these personas for further information on the two amazing people!

Sketches

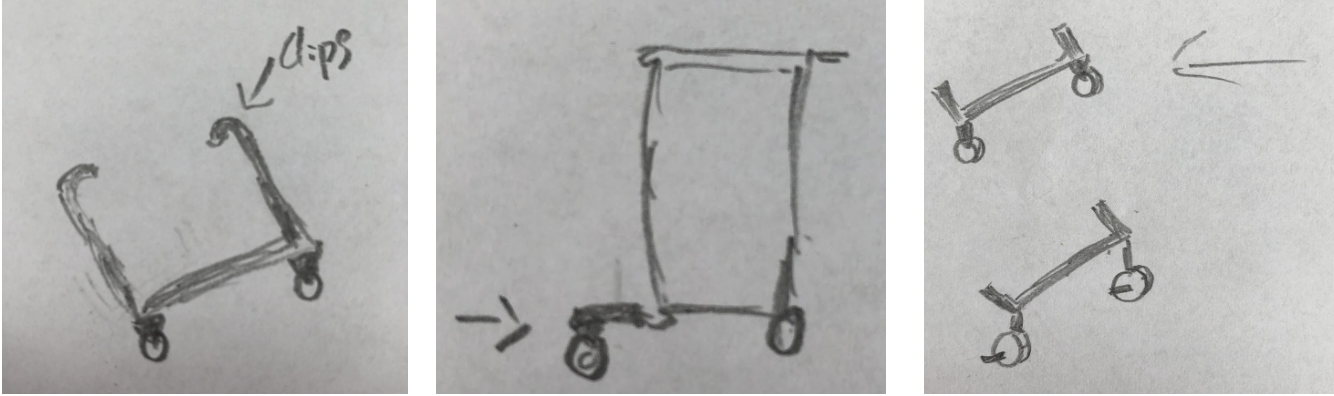

With some of the basic research down, I decided to move on to sketches; so I started off with a very basic drawing that can hardly even be called a wireframe. I was imagining having a bin with four wheels that can spin - like a shopping trolley. This in theory would allow for smoother movement, meaning less awkward shifting of the bin and therefore hopefully allowing more people to be able to maneuver it as it requires less strength to shift around. Looking at some of the accessible household bins, there is a handle on the sides so I included this in also as well as a raised handlebar at 45 degrees on the upper lid. The idea behind the raised handlebar was to allow for easy pulling of the bin as well as hopefully being easier to push down to achieve two-wheel movement (like a box trolley).

Upper Handle

Side Handle

Four Wheels

At this point, I thought I would get some ‘user feedback’. I say this lightly as unfortunately, I don’t currently have any contacts with anyone with a disability. This is a major upset for me as I really wanted to design something meaningful and helpful to others and without my targeted user’s feedback… I can only go so far. Nevertheless, I didn’t want this to stop this process. I started asking those around me about my initial design (wireframe if you will), starting with my family and friends. I guess this is more of a Guerilla/Hallway testing sort of feedback, rather than formal well defined user feedback.

First I asked my sister who works as a Service Designer for her opinion. She loved my idea but had reservations about the four-wheel design in regards to it staying in one place. With four wheels she expressed her concerns about it staying in place during winds etc. How I didn't think of this issue earlier is beyond me - but that's the usefulness of even hallway testing. We both then thought it may be good to put some sort of braking mechanism in with the wheels. I took this feedback and started thinking about the issues with even just a simple braking system - would this be enough on its own to stop movement in storms etc? How much money would be needed to design a bin with strong enough brakes? Bearing in mind that in theory, the council would have to pay for these bins to be made, the cost is a very important consideration.

I idealized a version of the bin that required it to be slotted into a wall hook, however, this would only solve the issue of the movement when by the side of the business, and not when put out for collection. As well as this, it would require everyone to install these hooks and the question of viability comes in here. How much would this also cost? Who would pay? The council or the homeowner? Could this really be effectively put into every household? All the signs were pointing to no on this idea.

The problem of the cost of scrapping all the current bins and paying for the build of a whole new style also raised an issue for me. Instead of scrapping the old bins entirely, could we not build upon the existing bin design? This would help cut the costs of scrapping and replacing the already enormous amount of bins already in existence and potentially cost less than replacing them with a whole new design.So I started ideating a version of the bin that acts as almost the reverse of taking off the training wheels of a bike. I designed another set of wheels to attach to the already existing wheelie bin design. Again they include movement in all directions but this time also includes a braking mechanism as well.

Now I know this sounds ridiculous considering the above issues I mentioned about the brakes, however, it is better than having none at all and since this would be attached to existing bins, it should - in theory - cost less than building it into the bin itself. I was imagining a shopping trolley-type wheel system but needed to make it more heavy-duty. I went about searching for shopping trolley wheels online and one of the first links that came up was for these heavy-duty wheels. I thought these were perfect for the idea that I had.

Now I know this sounds ridiculous considering the above issues I mentioned about the brakes, however, it is better than having none at all and since this would be attached to existing bins, it should - in theory - cost less than building it into the bin itself. I was imagining a shopping trolley-type wheel system but needed to make it more heavy-duty. I went about searching for shopping trolley wheels online and one of the first links that came up was for these heavy-duty wheels. I thought these were perfect for the idea that I had.

At this point, I decided to take a step back and think about this idea on a larger, holistic scale, rather than focusing too much on the granular details. How really is this going to work?

At this point, I was literally sitting at my desk actively imagining a set of these wheels being installed onto wheelie bins - how I didn’t start laughing at myself for focusing so much on trash. I was thinking about the height of the new wheels - should they be the same size height-wise or not? How helpful are fully rotational wheels when the other two are the only 2-way?

Here I did what Alan Dix taught me, take a step back. Take some time out. Busywork is a good thing here.

So, after a quick break I settled back down and gave it another think over, starting with the manouverablilty of the bin itself with these wheels attached. Specifically thinking about how useful the rotational wheels can be when the handle bar of the bin is on the side with the 2 directional wheels. If you pushed it yes it would move easier however could it turn easier?

For some reason the idea of front and rear wheel drive came to mind. Now I love the F1 and everything about it but I can hardly say I know a lot about the cars themselves - so I went into researching the mechanics and reasoning befind front and rear wheel drive to both see hope they qworked and what the reasoning behind choosing one over the other would be. Now I know the bins arent cars and dont have a motor but I am thinking specifically about the physics behind this (finally utilising that A I got in physics at GCSE).

After a bit of reading I realised that essentially, due to the handles of the existing bins being where they are, we are working with the bin equivalent of rear wheel drive, with all for momentum coming from the back. So with this in mind I realised that just like a car, just becasue the rear wheels don’t (neccissarily) move in tandem with the front when steering, the same would apply in this case. I realise how long it took me to realise that but I am not a car mechanic and if I was, god help anyone who got in said car.

‘Prototyping’

I’m using the word prototyping very lightly here 😅

Regardless, with all the above in mind, I realised that yes, indeed this could work well. So again I wanted to take a more holistic view of my idea. We have the original design, and we are adding to it. The bin exists and we are clipping a set of wheels to the front to allow for more convenient and easier movement.

So I decided this was the time to start doing some prototyping. I moved on to using photoshop to flesh my idea out more.

-

Here I pulled an image of a standard council wheelie bin and simply used the pen tool to ‘draw’ out there the mechanism would clip onto.

-

From here I started adding some actual images to it starting with the wheels.

-

Then added in the rest of the mechanism using an image of eco-friendly plastic boarding. So I know this is rather messy but I guess we can call it the first ‘more fleshed out’ design.

Now that I could sort of see it more I knew I was going down the right lines but was I heck going to settle with that image. So I went to make a sort of prototype using Adobe Illustrator. I started off using 3D shapes to create an image of heavy-duty wheels and then placed that ontop of the bin image I already had.

From here I knew I had definitely settled on this idea and decided to take it back for some Guerilla/Hallway testing. The idea of adding onto the existing design went down really well. The one thing noted for change would be for the mechanism to be made from eco-firendly, recycled material as much as it can be. I thought this was a brilliant idea. Not just because of the commercial viability it would bring, but because it’s something that didn't even enter my mind. I was too focused on the design to think about the materials. This is why research and feedback is so vital. As well as this, the idea of the raised handle bar came back up. Why wasn’t it kept in the design?

Well to put it simply, I thought that with it being attachable the handle bar just wouldn't be possible. However, I realised that I could add it as an extension to the wheels. The wheel mechanism would need to clip under and around the bin (under being because it needs to clip around the existing wheel structure) to stay in place so I could continue the design up and behind the bin and essentially add another handle.

I quickly threw this together to

kind of show what I was envisioning.

More Research…

So from here, I knew I had designed what I wanted and wanted to stop myself here before going too far with it (also noting that without the ability to get meaningful and accurate feedback, I had assumed enough already of what is needed). Moving on I decided to start researching the best type of eco-friendly material to use for the framework of the product.

After doing research into the best sustainable building materials, I made the table below of the most commonly mentioned materials, including their pros and cons.

Find the link to the table in a Google Document here.

I quickly ruled out recycled wood and bamboo as they are prone to degradation in the wet. If you live in England you would know the weather isn’t exactly always sunny and warm, so anything that needs to be outdoors all the time would need to withstand all weather types.

Eliminating bamboo and wood from the list of potentials leaves me with; recycled plastics, recycled metals, and cork. I quite liked the idea of using cork for the framework, more than recycled plastic and steel. With it being more versatile and eco-friendly in the first place, I favored this over the alternatives. Cork is impermeable just like plastic and steel, naturally fireproof, is flexible, and lightweight also. Cork is organic and quickly ‘re-grows’, unlike steel and plastic which take a lot of energy to be manufactured and even recycled in the first place.

I feel it is appropriate to address the cons of using cork, however - that being that it becomes more brittle over time and is costly to ship. Natural cork however is both fireproof and can last up to 50 years before becoming brittle. And the problems with the shipment? Because cork is so light, it can easily be shipped with other products, helping decrease the overall cost (financially and environmentally) of transportation.

Having settled on using cork to design the frame, I had to move on to the wheels, and simply typing ‘eco-friendly heavy-duty wheels’ brought up a couple of good options. The first option that came up was the above from amazon, made using recycled rubber and stainless steel. The second I found at this company that makes heavy-duty wheels made of 100% recycled aluminum. Melding these two designs together, I could propose having the wheel made of recycled aluminum with a recycled rubber tire.

I think it is important to note here why I decided to use recycled metals in this case. This is simply because it seems to be the best material for moving parts, unlike bamboo or cork which would be more prone to degradation with such a large weight put on it and how it would stand when the pressure of the brakes are applied onto it. Mental seems to be the best option in this case for ‘wear and tear’ purposes.

So, with this all in mind, and the usefulness of the pre-set materials effect on Adobe Illustrator, I changed the materials from metal to cork. Hopefully this gives the general idea of how I want the mechanism to look, I decided to put together a specifications document.

Final Stretch!

So after developing the above document. I decided I would draw out the ‘final draft’ as such, highlighting the handles, cork frame, and wheels.

I’ll explain the image to the left a bit. The drawing (rather poorly - apologies for my terrible drawing skills 😅) depicts the frame that would slot onto the existing wheelie bin. The top left shows a ‘zoomed in’ version of the top additional handle, which has braille describing which bin it is (garden, recycling, etc) as well as having two hollowed-out handlebar spaces with padding to allow for easy gripping.

The braille and handlebar spaces are repeated on the middle section of the bin, with handles on the three sides (front, left, and right) of the bin.

The arch on the bottom left of the frame is to show how it would fit and wrap around the existing wheel. Finally the wheels at the bottom are again ‘zoomed in’ to show that they will be made from 100% recycled aluminum and rubber.

I then took this final sketch and used Illustrator and Photoshop in a rather sad attempt to bring it more to life. The image shows the cork frame, braille and handlebar spaces as well as the heavy duty wheels and wheel arches.

Again, I know this isn’t the best ‘prototype’ in the world but please bear with my newness to this 😂

Naming Time!

With this, I knew I needed a name. I brainstormed a few on a Figma board, and then colour coded them from least favourite to most favourite (pink/red being the least, orange being in the middle and green being my favourites). The following names were purly a result of me writing down the first things that came to my head in a timed one minute interval.

So as you may be able to see, to the left is an image of a Figma board with a few names brainstormed and colour-coded.

‘BinEase’ and ‘EasyBin’ were straight away ruled out 😂 Eco-Mold and Extension I thought were alright but just were a bit lackluster. I thought the remaining two were my best shot - ‘Addition’ (with the A standing for Accessible) and ‘Just A Bin’ (again with the A Standing for accessible).

*A friend of mine suggested ‘Wheelie Roller’ and ‘Wheelie Easy’ and I’d like to give a honourable mention to those two, especially the latter! *

In the end, I decided A’ddition (with the apostrophe so emphasising the ‘A’) was going to be the name. I thought it sounded a bit more professional than ‘Wheelie Easy’ (sorry James I really do love the name though 😂) and it says what the product is quite well: Accessible Addition.

So in the end…

…I hope I managed to create a hypothetical product that would, hopefully, be at least somewhat helpful to those with disabilities of different kinds. Having my two personas, Issac and Alessia, was definitely helpful as I didn’t have the access to appropriate user feedback throughout the process. Without them to reflect on, I know for sure I would have not included details like the braille for descriptions and the middle handles as well that allow for easy reach.

This was a great project for me to work on and practice with accessibility at the heart of it as well as building my skills in the ‘product design’ field. I would love to one day be able to properly make a 3D prototype for it with specialist software but for now, I think I’ve done alright especially considering the lack of real user feedback and testing.

So, to wrap it all up, please find below the link once again to the specifications document and final sketch and design ☺️